Whether it be your bespoke/prototype developments through to batch production fabrications, we have the finishing capability to meet specification every time

Finishing Services

Finishing Services

Whether it be your bespoke/prototype developments through to batch production fabrications, we have the finishing capability to meet specification every time

In common with everything else we do, our finishing services are provided to customers on a subcontract or outsourced basis, as well as being integral to our own production process.

TS Metals’ painting services are both comprehensive and flexible so that you can specify end-to-end finishing – or only the elements you are unable to carry out in-house.

Rest assured that our fabrications can be painted and finished fully in line with the project specifications, we can also recommend the paint finish that would be required to meet the harshest of environments from hot desert conditions at 50°C to the wettest or coldest of conditions on an off-shore platform where salt-water also needs to be a consideration.

Painting is carried out at one of our advanced spray booths here in Rugby by qualified and experienced painters.

Our painting area is specifically designed to allow us to offer a range of different wet spray paint finishes for all fabrications, from priming to full multicoat specifications, using industrial paint up to marine standard, from all the main manufacturers or working with free issue paint if preferred. We use conventional spray guns & pressure pots to ensure a clean finish. All finishes are designed to be hard-wearing and durable but finished to the highest of standards.

We can also supply powder coating and galvanising, again advising on the most suitable finish for your project.

If you need to outsource your painting needs, please contact us to discuss your requirements.

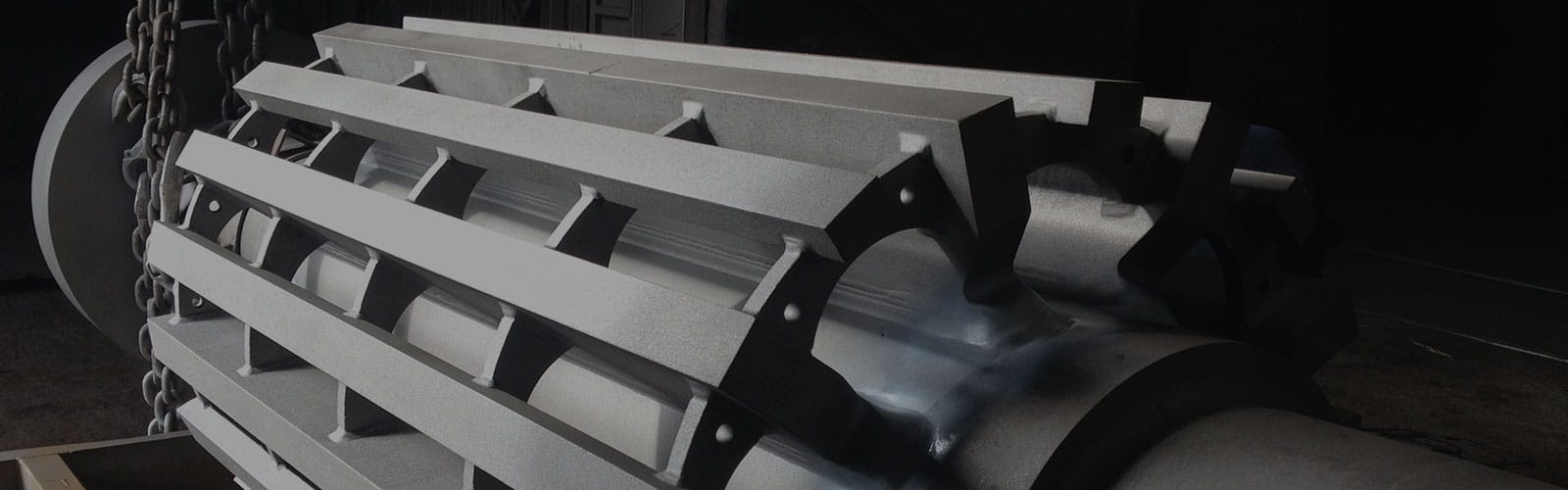

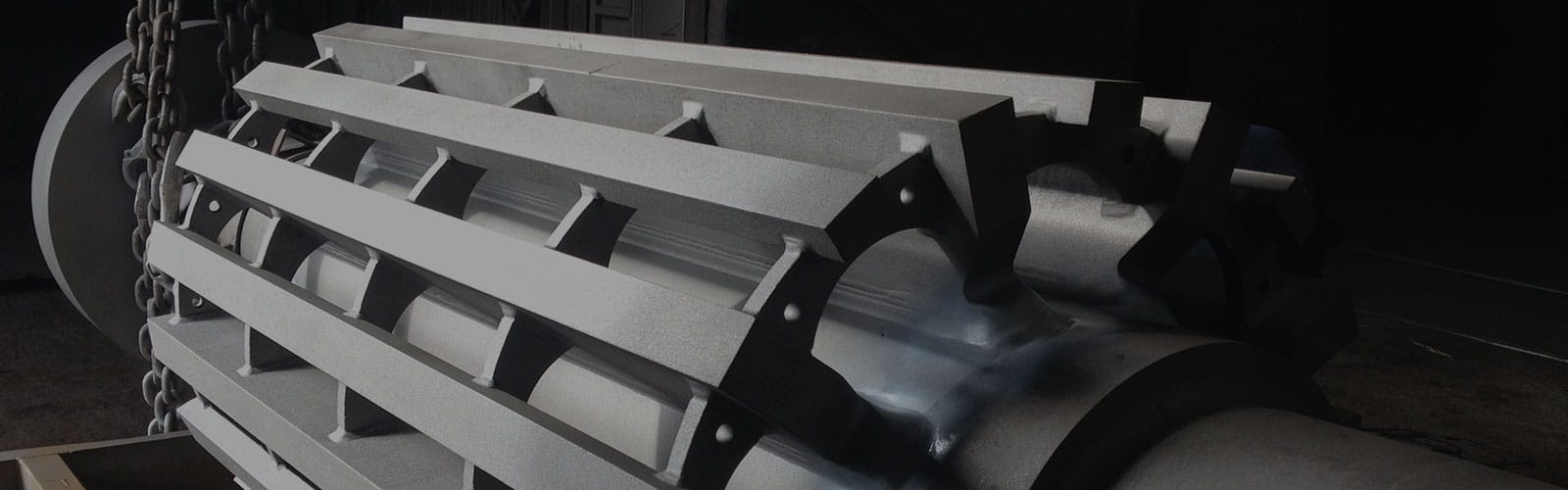

For a high quality paint finish, preparation is key. TS Metals provides a highly efficient and versatile shot blasting facility for the manufacturing, engineering and refurbishment industries in the West Midlands and further afield. Shot blasting is also an integral part of our end-to-end metal fabrication, welding and finishing service.

Shot blasting is an effective method of preparing surfaces with a suitable surface finish prior to painting or other finishing methods. It can also be used to remove rust, scale or existing unwanted coatings to expose clean bare metal prior to refurbishment or repair.

Our large, 149m3 blast booth enables us to handle most components and assemblies and delivers superior speed and economy to alternative cleaning and surface finishing methods. Using G24 steel shot, we comply with BS EN ISO 11124/5/6/7, to ensure conformance to Visual Standard SA2.5 of BS EN ISO 8503.

If you need to outsource your shot blasting needs, please contact us to discuss your requirements.

To summarise, a range of finishing services can be provided including;.